When it comes to keeping your Massey Ferguson tractor running smoothly and efficiently, few components are as vital as the fuel injector pump and fuel injectors. These precision-engineered parts ensure your diesel engine receives the right amount of fuel at the right time — maximising power, minimising fuel consumption, and keeping emissions low. Over time, even the best components wear out, leading to poor performance, hard starting, and increased fuel usage.

This comprehensive guide explains how to identify when it’s time to replace your Massey Ferguson fuel injectors and Massey Ferguson injection pump, what parts are required for maintenance, and how to fit replacements correctly.

Understanding the Role of the Fuel System

The Massey Ferguson fuel injector pump and fuel injectors form the heart of the diesel fuel delivery system. Together, they ensure precise timing and atomisation of fuel for clean and efficient combustion.

- The Massey Ferguson injection pump regulates both the fuel volume and the high pressure needed for injection.

- The Massey Ferguson fuel injectors spray fuel into the cylinders in a fine mist for maximum burn efficiency.

Contaminated fuel, age, and wear can lead to malfunctioning injectors or a weak pump, resulting in rough running and reduced power. Understanding how they work helps you identify issues early.

Common Symptoms of Failing Fuel Injectors and Pumps

Watch out for these warning signs that your Massey Ferguson injectors or fuel injector pump may be due for replacement:

- Hard Starting or No Start: Low fuel pressure or pump failure can prevent the engine from starting.

- Rough Idle or Misfiring: Uneven spray patterns from worn injectors cause rough running.

- Poor Fuel Economy: A worn injection pump or leaking injectors can waste fuel.

- Excessive Exhaust Smoke: White or black smoke often points to poor atomisation or incorrect timing.

- Loss of Power: Insufficient fuel delivery causes sluggish acceleration and reduced torque.

Addressing these issues early prevents costly repairs and downtime.

Diagnosing Fuel Injector and Pump Problems

Before replacing components, confirm whether the fault lies in the Massey Ferguson fuel injector pump, the fuel injectors, or elsewhere in the system.

- Check Fuel Quality: Contaminated or old diesel can mimic injector issues.

- Inspect Return Flow: Excessive return fuel may indicate leaking injectors.

- Measure Fuel Pressure: Low pressure readings suggest a weak injection pump.

- Cylinder Isolation Test: Disabling one injector at a time helps pinpoint individual faults.

For best results, use professional diagnostic tools to verify spray patterns and pump calibration.

Choosing the Right Replacement Parts

Using genuine or high-quality replacement Massey Ferguson fuel injectors and fuel injector pumps ensures reliable performance and long-term value. Always verify compatibility with your specific tractor model and engine type.

OEM parts are built to the exact tolerances of the original system, while high-quality aftermarket alternatives can offer good performance at lower cost — provided they are tested and calibrated. Reputable suppliers such as ourselves at masseyparts.com and authorised Massey Ferguson dealers stock both options.

Step-by-Step Replacement Overview

Replacing Massey Ferguson fuel injectors or the fuel injector pump requires precision and cleanliness. Below is a general overview of the process:

-

Preparation

- Disconnect the battery and clean around the fuel components.

- Drain the fuel lines to avoid contamination.

- Label all hoses and connectors before removal.

-

Removing the Fuel Injector Pump

- Loosen fuel lines and disconnect electrical connectors.

- Remove mounting bolts and timing gear.

- Be careful not to disturb timing unless recalibration is planned.

-

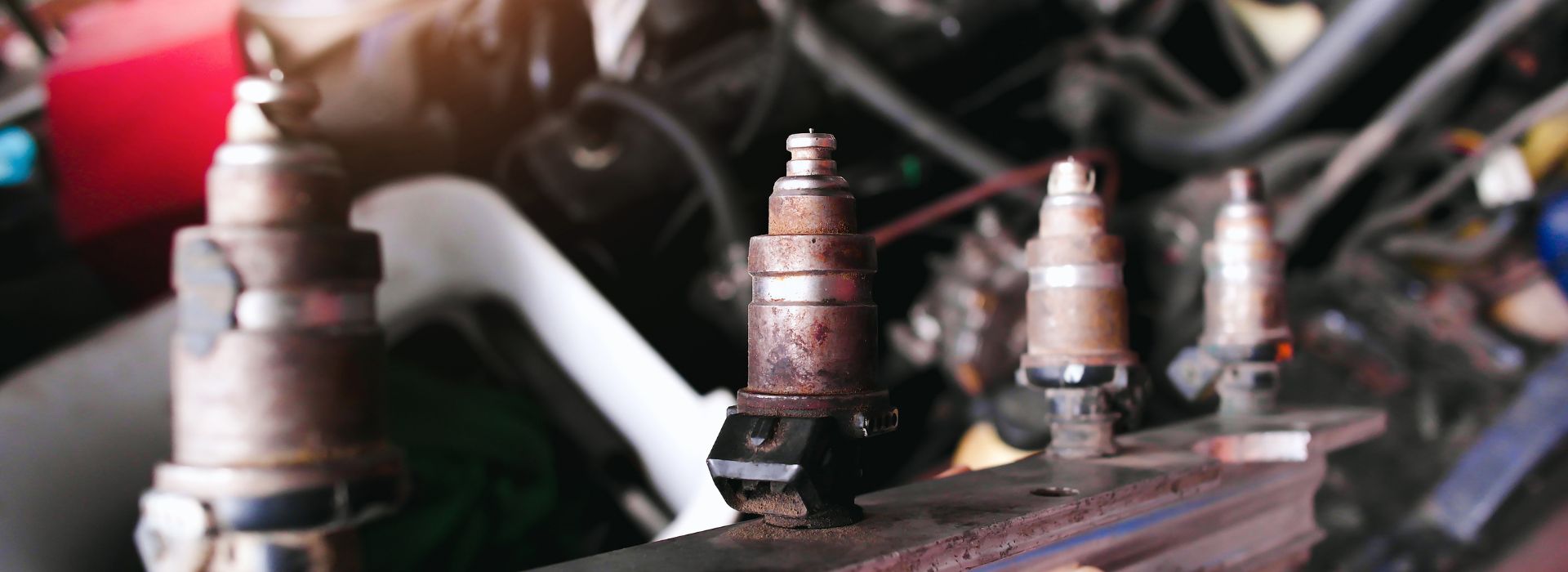

Removing Fuel Injectors

- Remove injector clamps and lines.

- Extract the injectors carefully using the proper puller.

- Clean seats and replace copper washers or O-rings.

-

Installing New Components

- Fit the new Massey Ferguson injectors and torque them correctly.

- Install the Massey Ferguson injection pump, aligning timing marks.

- Reconnect lines and fittings securely.

-

Bleeding and Testing

- Prime the fuel system to remove trapped air.

- Start the engine, check for leaks, and ensure smooth idling and strong throttle response.

If unsure, have a certified diesel technician perform the replacement — proper timing and torque settings are critical for engine health.

Parts Needed to Maintain Your Fuel Injectors and Pumps

Regular maintenance of your Massey Ferguson fuel injector pump and fuel injectors depends on several supporting components. Neglecting these parts can shorten injector life and reduce engine performance. Here’s what you need to keep on hand for optimal maintenance:

Your first line of defence against contamination. Replace main and secondary fuel filters regularly to protect injectors and the injection pump from dirt and water.

-

Pre-Fuel Filter or Water Separator

Removes water and larger debris before the diesel reaches the main filter. Drain the separator frequently to prevent corrosion inside the Massey Ferguson fuel injector pump.

-

Fuel Lines and Hoses

Inspect both feed and return lines for cracks or leaks. Worn lines allow air to enter the system, disrupting fuel pressure and injection timing.

- Injector Seals and Copper Washers

Always replace these when changing injectors. They ensure airtight sealing between injector and cylinder head, preventing combustion leaks and compression loss.

-

Fuel Additives or Injector Cleaners

Diesel conditioners help clean internal injector tips, dissolve carbon deposits, and provide lubrication for the injection pump. Add them to your tank every few hundred hours.

-

Fuel Tank Strainer or Pick-Up Filter

Catches debris inside the tank before it reaches the filters. Cleaning or replacing it regularly prevents starvation of the fuel injector pump.

If servicing or rebuilding the Massey Ferguson injection pump, use a new gasket and seal kit to prevent fuel and air leaks that can affect performance.

-

Banjo Bolts and Washers

Small but essential — they secure high-pressure fuel lines and prevent leaks. Replace any that appear damaged or worn.

-

Fuel Pressure Regulator

Ensures stable pressure delivery throughout the system. Replace if pressure fluctuates or if the engine runs unevenly.

-

Pump Drive Belt or Coupling

Some models use a mechanical coupling or belt to drive the fuel injection pump. Inspect and replace according to your service schedule to maintain precise timing.

-

Fuel Priming Pump

A healthy priming pump ensures smooth startup after servicing filters or lines. Replace or rebuild it if it loses pressure or leaks.

Inspect regularly for vibration damage or loose fittings. Tight, clean lines ensure consistent pressure delivery from the pump to the injectors.

Maintenance Tips for Longevity

A little preventive care goes a long way in extending the life of your Massey Ferguson fuel injectors and fuel injector pump.

Follow these expert tips:

- Replace fuel filters every 250–500 hours of operation.

- Drain the water separator weekly during wet months.

- Use clean, high-quality diesel fuel only.

- Add fuel conditioner before long-term storage.

- Check for leaks and torque settings regularly.

Routine maintenance ensures that your Massey Ferguson injectors continue to deliver consistent fuel spray and optimal combustion — keeping your engine powerful and efficient.

Why Genuine Parts Matter

Genuine Massey Ferguson fuel injectors and fuel injector pumps are manufactured to the same standards as the original factory components. They offer:

- Precise fuel delivery and spray patterns

- Reliable performance under heavy loads

- Longer service life and warranty protection

Inferior copies or uncalibrated rebuilt parts may save money initially but often result in poor fuel economy, hard starting, and reduced power. Always purchase from trusted suppliers with quality testing and calibration guarantees.

To Finish Off

Replacing or maintaining your fuel injectors and fuel injector pump is one of the most important aspects of keeping your Massey Ferguson tractor at peak performance. Whether you’re running a classic MF 135, a dependable 390, or a modern 7700-series model, ensuring your Massey Ferguson injection pump and fuel injectors are in perfect condition will maximise power, fuel efficiency, and reliability.

With proper diagnostics, quality replacement parts, and consistent maintenance — including the supporting components listed above — your Massey Ferguson engine will continue to deliver dependable performance season after season.

Need replacement parts for your Massey Ferguson Tractor? Browse our selection of Genuine, Economic and Used parts in our online shop. Or feel free to Contact Us if you have any queries or need assistance in choosing the right parts.