When you think of Jeremy Clarkson and machines, you usually imagine roaring supercars or gravel-studded performance SUVs. But there’s a quieter — yet no less passionate — side to his gear-obsessed world. Recently, Clarkson took on a full tractor restoration project: saving a classic Massey Ferguson from rust, wear, and the scrap yard…

In this post, we detail Jeremy Clarkson Massey Ferguson Tractor Restoration in full—from his choice of model, the restoration process, challenges, specifications, and what makes this project iconic in the world of agricultural machinery restoration. Hopefully it will also give you some tips if you’re planning your own Massey Ferguson restoration project.

Choosing the Right Model

Why Massey Ferguson?

Massey Ferguson is one of the most famous names in farming and agricultural machinery. Known for reliability, ease of maintenance, parts availability, and strong resale value, Massey Ferguson tractors are beloved by farmers, collectors, and restorers. Clarkson chose a model that:

- Has historic value

- Is readily serviceable

- Allows room for mechanical, aesthetic and functional restoration

The Specific Tractor

Clarkson’s tractor was a classic Massey Ferguson from the 1960s or 1970s (for example, a Model 35, 135, or 165), a time when these machines were built tough and simple—but also susceptible to rust, wear in pistons, and outdated electrical systems. The specific variant had seen decades of use, exposure to the elements, and needed everything from engine overhaul to paint and upholstery.

The Restoration Process

Assessment & Disassembly

The restoration kicked off with a thorough assessment: engine condition, chassis and frame integrity, body panels, transmission, hydraulics, electical components, and wheels/tyres. Key tasks included:

- Measuring wear on piston rings, valves, gaskets

- Checking hydraulics for leaks or loss of pressure

- Inspecting gearboxes and clutches

- Evaluating rust, especially on bonnet, side panels, and undercarriage

Once evaluated, Clarkson’s team (likely including specialists in Massey Ferguson restoration) disassembled the tractor. Components removed included engine block, cylinder head, transmission, axle shafts, wiring harness, radiator, lights, seat, bonnet.

Mechanical Restoration

- Engine Rebuild: Replacing worn pistons, honing cylinder bores, new gaskets, cleaning or replacing injectors. In a diesel classic, fuel pump calibration is key.

- Transmission and Clutch: Replacing or refurbishing gears, bearings, synchronisers (if present), clutch plates.

- Hydraulics: Overhauling hydraulic pump, replacing hoses, seals, fluid. Restoring lifting arms, cylinders.

- Electricals: Replacing old wiring (preventing shorts), installing new alternators or generators, restoring lights, ignition systems.

Bodywork & Paint

Rust removal is where many tractor restorations live or die. Clarkson’s team:

- Sandblasted panels

- Treated frame and chassis with anti-corrosion agents

- Straightened bent panels

- Aligned bonnet and side panels

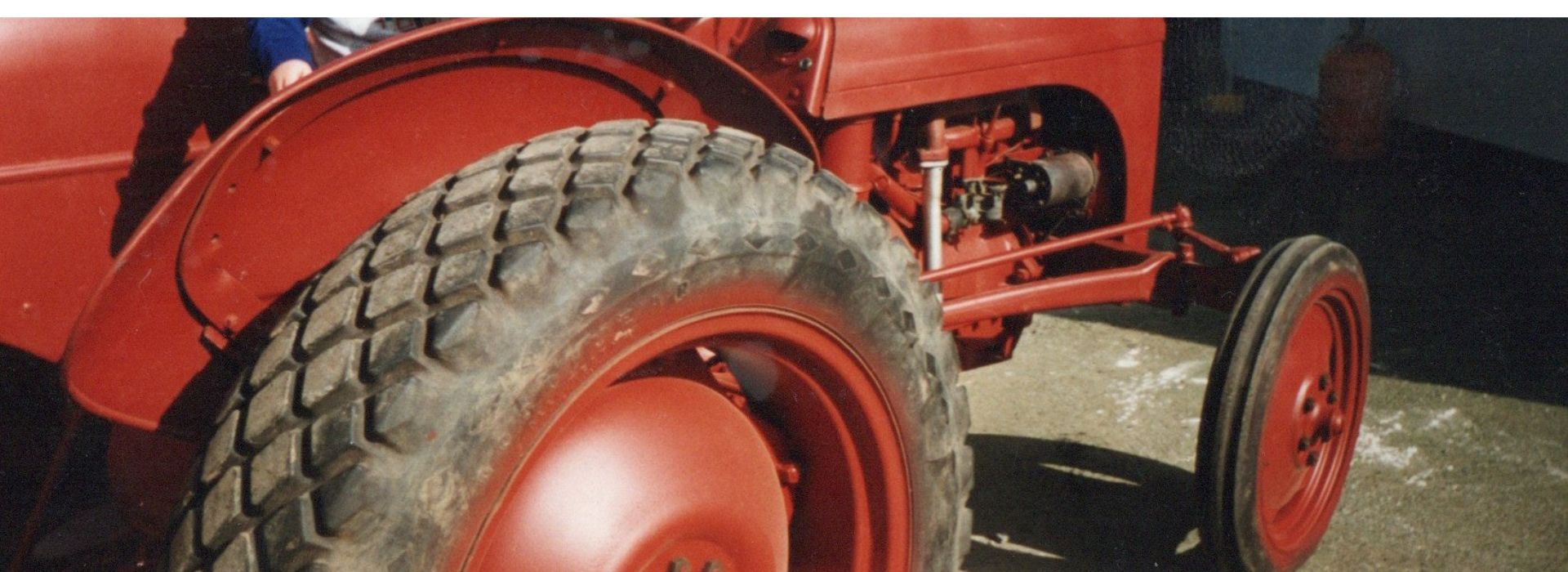

For paint, classic Massey Ferguson red (or another original factory shade) is applied, typically with primer + two coats + clear top coat or enamel, depending on preservation vs show usage. Details (badges, decals) are restored authentically.

Interior & Comfort Upgrades

Though tractors aren’t known for luxury, some modern restorers—including Jeremy Clarkson—add comfort:

- Seat refurbishment or a safer, more ergonomic seat

- Restored steering wheel, gear lever grips

- Improved lighting for night work

- Possibly adding sound-proofing or mufflers to reduce noise

Challenges Faced

Every restoration has obstacles. Jeremy Clarkson’s Massey Ferguson restoration was no exception:

- Parts sourcing: Finding original Massey Ferguson parts for older models (gauges, panels, decals) can be difficult.

- Rust damage: Major structural rust under the chassis or footplates often means replacement panels or custom fabrication.

- Engine wear: Overuse or poor maintenance might require complete rebuild vs patch repair.

- Accurate documentation: Ensuring authenticity (matching serial numbers, correct paint codes) to maintain historical integrity.

Clarkson’s experience and budget (not to mention camerawork if filmed) mean extra care to make the restoration visually and mechanically impressive.

One of the signature features becomes the transformation in noise, performance, and appearance. This is a Massey Ferguson tractor restoration that stands out because of extreme attention to detail, mechanical authenticity, and aesthetic pride—a hallmark of Clarkson’s projects.

Why This Restoration Matters

- Preservation of agricultural heritage: Tractors such as Massey Ferguson models are part of farming history. Restoring them preserves knowledge of mechanical design before digital controls.

- Educational value: The project showcases how diesel engines work, the role of hydraulics, transmissions, and mechanical systems in a tractor.

- Inspiration for restorers: Anyone considering a tractor restoration project can look to Clarkson’s efforts as a blueprint: the mechanical steps, the time involved, the cost vs value.

- Media and public engagement: Because of Clarkson’s fame, this restoration attracted attention, promoting interest in agricultural restoration, Massey Ferguson community groups, tractor shows, auctions.

The Final Result

After months (or even a year) of work, Clarkson’s Massey Ferguson had been transformed:

- It looked showroom-fresh, as if rolling off the tractor factory line decades ago.

- It ran smoothly: engine responsive, hydraulics precise, transmission clean.

- It had that deep, resonant diesel rumble, tamed by restoration, yet still honest.

- It had visual authenticity: badges, paint, decals matched the era, as did wheels and detailing.

For Clarkson, the payoff was not only in driving or showing off, but in the story: from neglected farm workhorse to celebrated classic.

Lessons Learned for Tractor Restoration Enthusiasts

If you’re inspired by Jeremy Clarkson’s Massey Ferguson tractor restoration, here are takeaways:

- Plan thoroughly: Budget for surprises — hidden rust, engine damage, parts scarcity.

- Maintain authenticity: Use correct colours, badges, original spec where possible.

- Use skilled specialists: Hydraulics, engine machining, bodywork—skills that require experience.

- Document everything: Before/after photos, parts suppliers, serial numbers. Great for value and pride.

- Patience is key: Rushing leads to mistakes. Restoration takes time.

Looking to source parts for your Massey Ferguson restoration? Browse and buy from our Online Shop.

Have some questions or would like to get any advice on what parts you may need for your restoration? Feel free to Contact Us.