Owners of Massey Ferguson 300, 500, 600, 3000, 3100, 3600, 4200 and 4300 series tractors are in a sweet spot: you’ve got serious workhorses with decent electrics, but they’re now old enough that charging problems, brittle wiring and tired switches can be a bit of a frustration.

This guide looks at practical electrical upgrades and maintenance for these “modern classics” and finishes with a clear buying guide of the replacement parts you’re likely to need.

Why focus on alternators, regulators and looms?

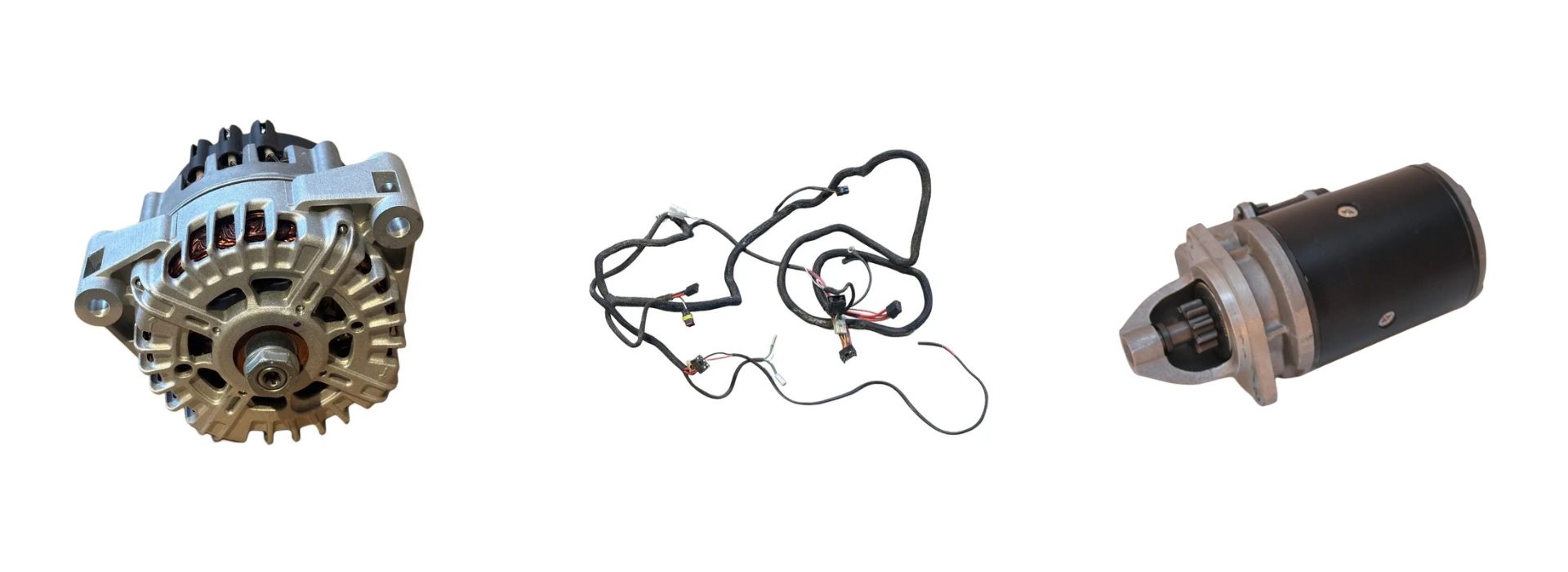

On these tractors, most electrical problems trace back to three areas:

- A weak or failing alternator / regulator

- Corroded or damaged wiring looms and connectors

- Tired starter, switches or earths that drag the whole system down

Specialist suppliers now stock complete electrical ranges for MF 3000/3100 and 4200/4300 series – alternators, starters, looms, sensors, switches and more – because these parts are recognised wear items on older Masseys.

At the same time, general tractor alternator guides all say the same thing: if your system can hold around 14.0–14.4 V at the battery with the engine running, the alternator and wiring are generally healthy; if it can’t, something in the charging or wiring system needs attention. You can find out more here on how to test your alternator.

Alternator upgrades on 300, 500 and 600 series

Most 300, 500 and 600 series tractors already use alternators rather than dynamos, but they were sized for halogen work lights and minimal electronics, not today’s LED bars, monitors and GPS.

Common upgrades here are:

- Replacing the tired original alternator with a modern 65–120 A unit, often a Mahle, Lucas or similar listed to suit specific MF models.

- At the very early end (some 300-series crossovers), converting from a dynamo using a complete dynamo-to-alternator kit, which typically includes alternator, brackets, short wiring harness, ignition switch and charge warning lamp.

When you fit a higher-output alternator, always:

- Match the pulley type and belt width

- Upgrade the main charge cable and earths if they look marginal

- Verify output with a voltmeter at the battery after installation. Find more tips for this here.

Electrical reliability on MF 3000, 3100 and 3600 series

The 3000/3100/3600 tractors (e.g. 3060, 3065, 3080, 3635) added Autotronic/Datatronic control, making clean power and good wiring even more important. Parts catalogues for the MF 3065, for example, show a wide electrical section: alternators, starters, looms, sensors, gauges and more.

Typical upgrades and maintenance:

- Model-specific alternator replacement or uprating – there are 65 A and larger units designed to bolt straight on to 3000-series brackets.

- Renewing engine-bay and cab looms, especially around the Autotronic box and fuse panel, where heat and vibration cause broken wires.

- Replacing ageing sensors, dash switches and earth straps so ECU and dash readings stay stable.

If you’re troubleshooting, a general guide to MF electrics (battery, alternator, wiring) is a good companion, especially for step-by-step checks. Have a look at our previous blog on this subject here.

4200 and 4300 series: loom health is everything

The 4200 and 4300 series (4215, 4220, 4225, 4235, 4255, 4270 etc.) push things further again: more relays, more sensors, more load through the fuse board. Electrical parts ranges for, say, the MF 4225 include switches, complete wiring looms, starter motors, alternators, gauges, sensors, tachometers, lights and bulbs – showing just how many potential failure points there are on a 20-plus-year-old tractor.

On these tractors, prioritise:

- A good quality OE-style alternator matched to the tractor (there are complete MF 4270 alternator units specifically for 4200/4300 series).

- Clean, heavy battery-to-starter and battery-to-chassis cables

- Careful inspection of loom runs over the transmission and rear axle, where movement and dirt attack insulation

Again, testing with a voltmeter at the battery is your first, simplest diagnostic. Find out more about testing your electrical system here.

Electrical parts buying guide for MF 300–4300 series

To make it easier to buy the right parts for your electrical system, here’s a “what you’ll need” guide for upgrading or maintaining electrics on these tractors.

-

Charging system

- Alternator (standard or uprated)

- 65–120 A units, tractor-specific for MF 3000/3100/3600 and 4200/4300, or universal units for 300/500/600.

- Voltage regulator / brush pack (where serviceable separately)

- Dynamo-to-alternator conversion kit for older machines: alternator, bracket, short loom, ignition switch, charge warning lamp.

- Drive belt and pulleys to suit the new alternator

-

Wiring looms and harness sections

- Main chassis/engine loom – from battery and starter forward around the engine bay.

- Cab/instrument panel loom – especially important on Autotronic 3000/3100/3600 tractors.

- Rear loom – lights, trailer socket and hitch switches.

- Special harnesses – Autotronic or series-specific harnesses and conversion looms for 3000/3100/3600; dedicated electrical sections for 4200/4300 series list these clearly.

Where you’re only repairing sections, buy correct-gauge automotive cable and, ideally, colour-coded wire to match the original loom.

-

Connectors, fuses and earths

- OE-style or waterproof multi-pin plugs and individual terminals

- Repair pigtails for common plugs (lights, sensors, trailer socket)

- Blade and glass fuses, plus replacement fuse holders or boards

- Relays for lights, glow plugs, PTO or transmission functions

- Heavy earth straps from battery to chassis and engine; MF electrical guides emphasise how often bad earths are behind “mystery” faults. You can learn more about this on our previous blog post here.

-

Starting system

- Starter motor – standard or high-torque upgrade, listed under electrical parts for MF 3000 and 4200/4300 series tractors.

- Starter solenoid – separate or integral.

- Battery-to-starter lead and battery-to-chassis lead (upgrade cable size if in doubt).

- Ignition switch + short harness – often sold as a complete electrical component for older MF series.

-

Batteries and protection

- Correct battery (capacity and terminal layout)

- Battery isolator switch and heavy isolator cables

- New battery terminals and covers

-

Lights, switches, sensors and instruments

- Headlamps, rear lamps and work lights – many owners now prefer LED units; MF parts categories list halogen and LED options by series.

- Bulbs or LED upgrades for indicators, stop/tail and dash illumination

- Dash switches for lights, hazards, wipers and heater fan

- Pedal/lever switches – clutch safety, brake light, handbrake warning

- Sensors & senders – oil pressure, coolant temperature, fuel level and, on later series, transmission pressure/temperature and speed sensors

- Gauges and tachometers – including electronic clusters on 3000/3100/3600 and 4200/4300 series.

Final checks after you’ve upgraded

Once you’ve fitted an alternator, tidied the loom and refreshed key components:

- Measure battery voltage engine off (around 12.6 V) and running (typically 14.0–14.4 V if the alternator and regulator are healthy). Read this article for more advice on battery health.

- Load the system with lights, fan and any monitors and look for stable voltage and non-flickering lamps.

- Feel for hot spots at cables, connectors and fuses after a few minutes under load.

- Keep a note of part numbers and wiring alterations for the service file.

Do that, and your MF 300, 500, 600, 3000, 3100, 3600, 4200 or 4300 will not only start better and charge properly, it’ll also be far easier to diagnose in future – and you’ll know exactly which electrical parts to keep on the shelf.

Have a query about your Massey Ferguson Tractor electrical system? Feel free to Contact Us. You can also buy replacement parts for your tractor on our Online Shop.